PVD Magnetron Sputtering

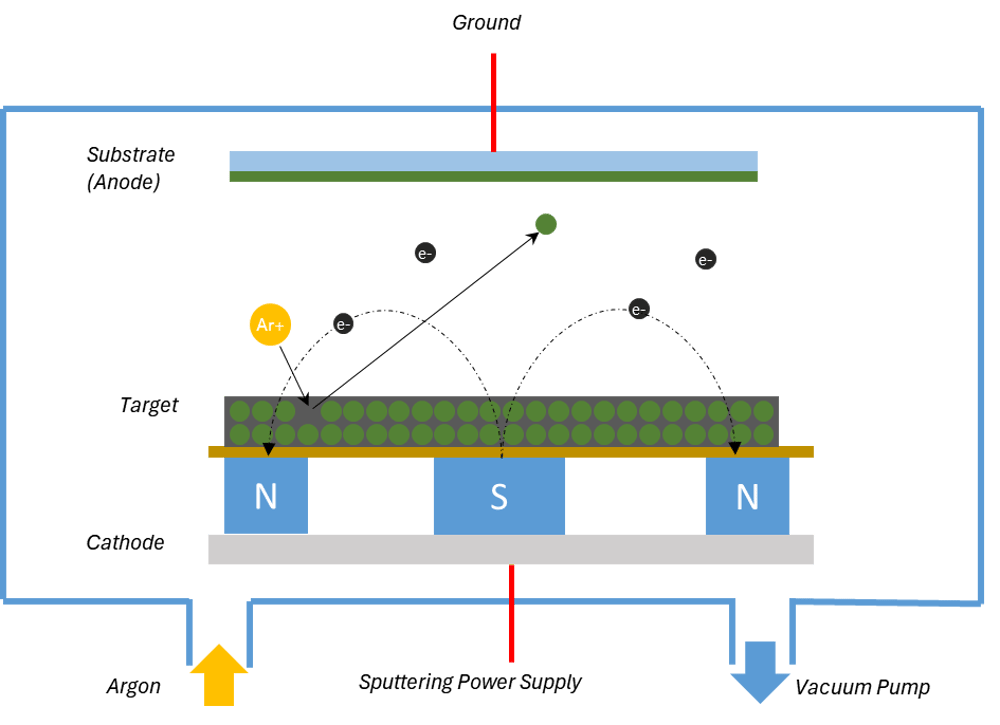

Magnetron sputtering is a physical vapor deposition (PVD) technique that uses a plasma to coat surfaces with thin films in high vacuum environment. It involves using strong magnets to confine electrons in a plasma near the surface of a target material, which creates a higher density plasma and faster deposition rates. The target is then struck by high-energy ions (Ar+) under the action of an electric field, which eject neutral atoms or molecules from the surface and deposit a thin film on the substrate.

The name comes from the use of strong magnet fields under the target to control the behavior of the charged ion particles. The dense plasma traps the electrons near the target surface due to the Lorentz force, causing them to move in spiral motions until they collide with argon atoms, producing more Ar+ to bombard the target and greatly increased ionization and spectric efficiency, which can increase the position rate by 10 to 100 times.

The process works by:

1. Generating and confining plasma near the target surface

2. Using strong magnets to confine the electrons in the plasma

3. Bombardment of the target surface by the high-energy ions

4. Liberation of atoms by the sputtering process, creating a vapor cloud

5. Movement of the vapor through the vacuum area, depositing onto a substrate surface to create a thin film covering

Magnetron sputtering is used for many materials science applications, such as: Coating microelectronics, Altering properties of materials, and Adding decorative films to products with the technical advantages below:

- The deposition rate is high and the deposition efficiency is high, suitable for large-scale application in industrial production

- Relatively low temperature process, suitable for coating on substrates such as plastics that are not resistant to high temperatures

- The deposited film has high purity, good density, good film uniformity, and strong film base bonding force

- A wide range of thin films of metals, alloys, oxides, etc. can be deposited

- Environmentally friendly and pollution-free